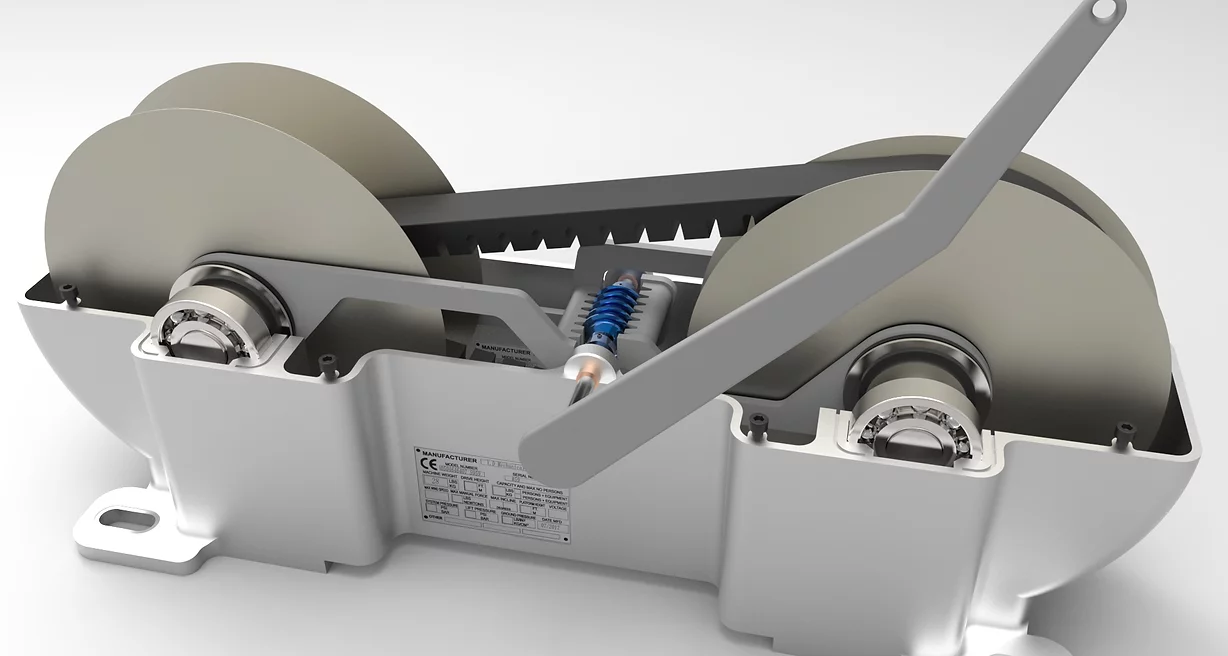

a design project of an industrial grade manual or automatic CVT. (Continually Variable Transmission) ..

Industrial Application C.V.T

תיאור

a CVT (continually variable transmission) is a mechanism that allows a driving ratio to change in a continuous manner, with a difference to conventional gears which uses a series of progressing cogs to do so. this method is not new and has been implemented with everyday products around us for years. some say it was Leonardo De Vinci who visualize a CVT design back in the 13th century. Modern days designs can vary, but the principle is more or less the same. check out this clip that explains a common CVT's operation.

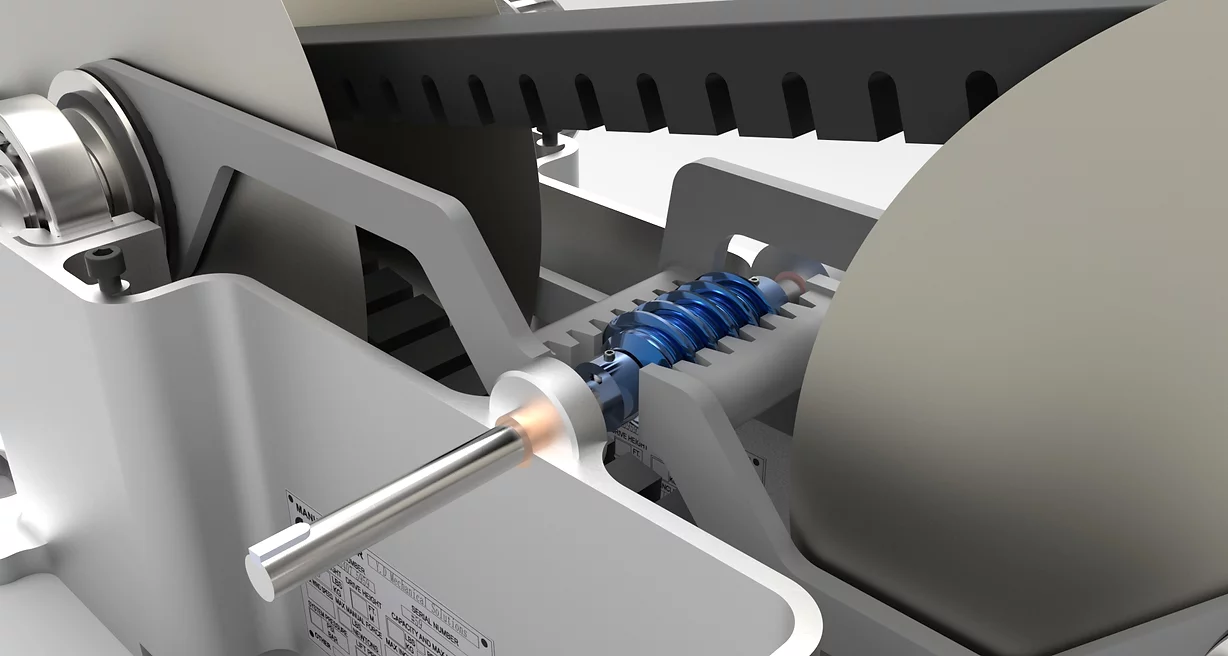

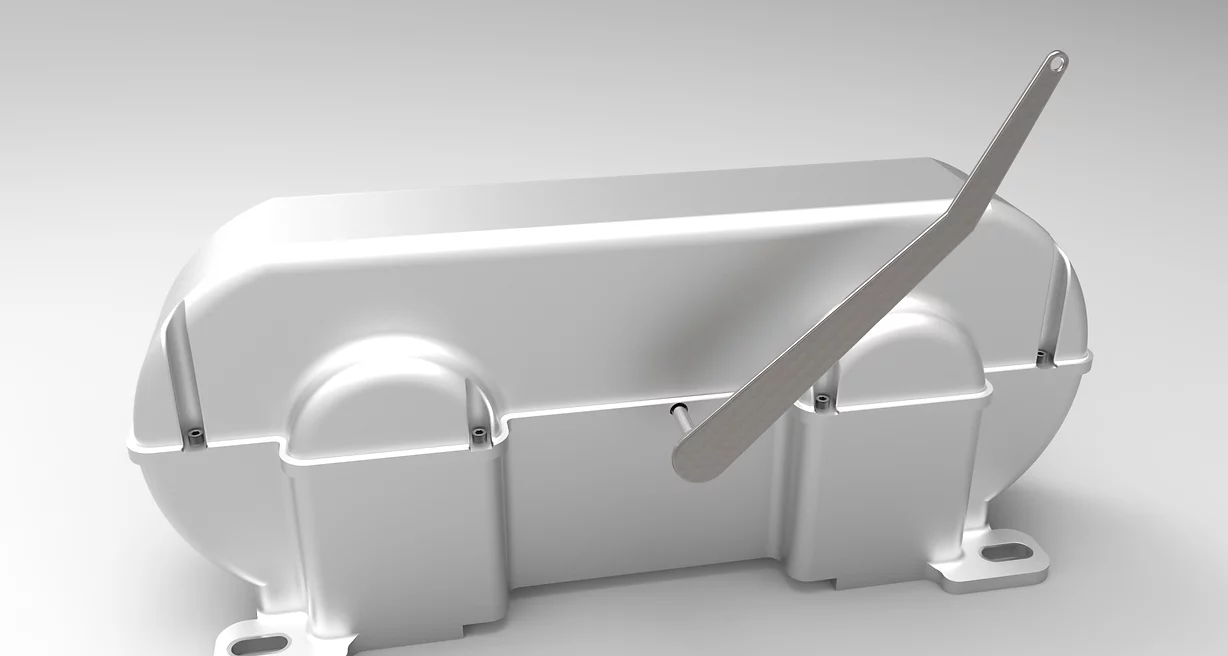

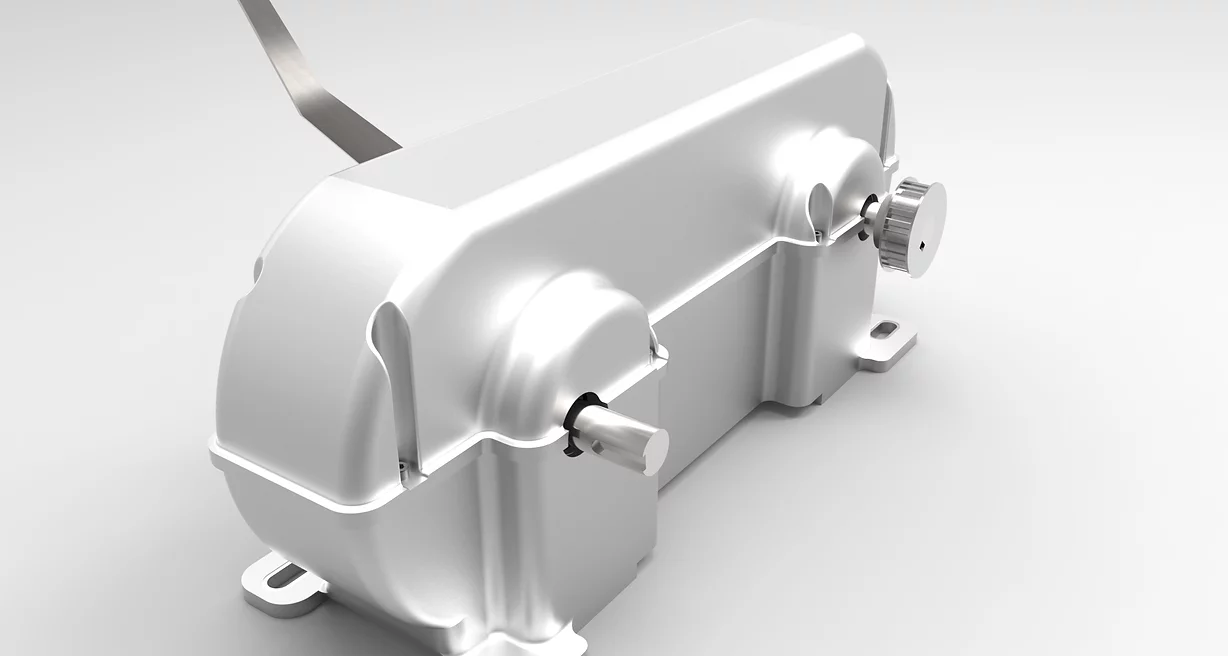

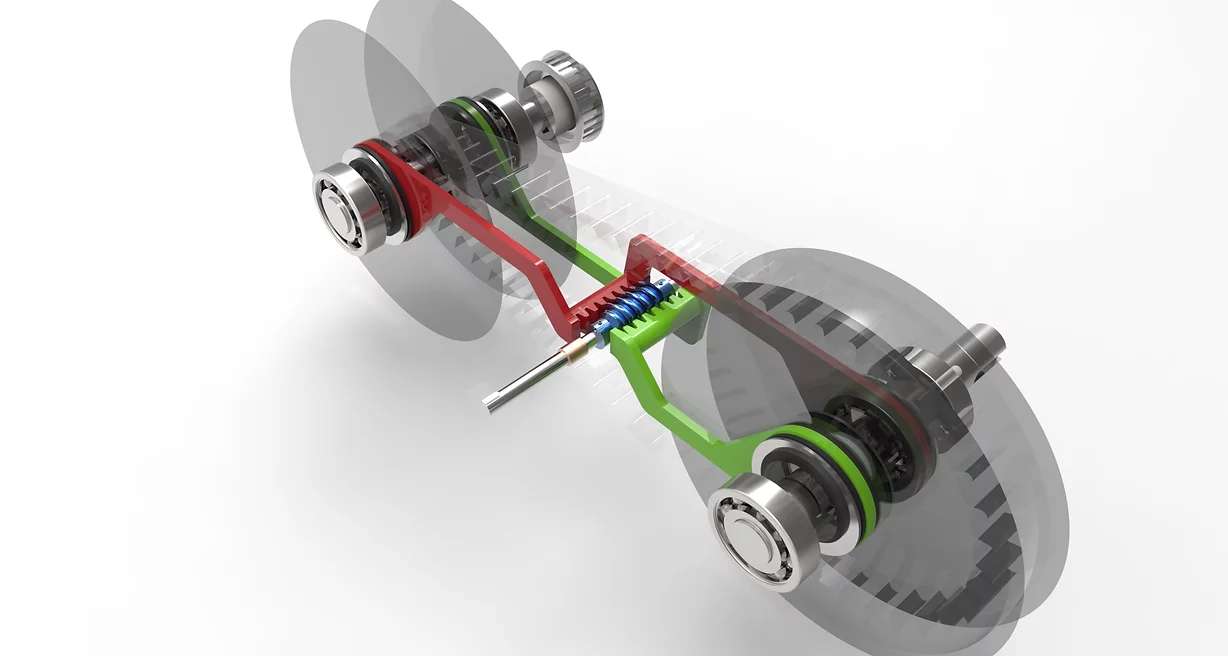

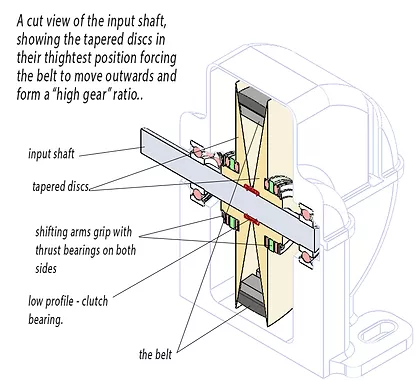

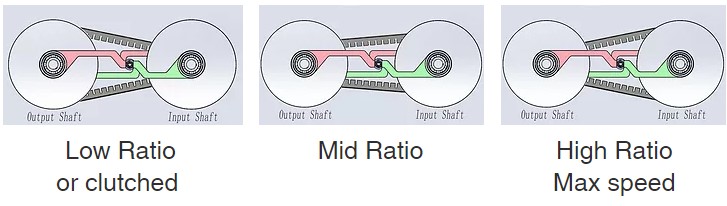

In my CVT design, a turn of a worm-gear (either manually by a leaver or electrically by a step motor), causes the set of 2 pairs of tapered conic discs to move. each pair is mounted on one of the shafts (input/ output) with the tapered faces towards each-other. when turning the worm gear, one pair of discs gets closer to each-other forcing the belt outward to a larger diameter, while at the same time the other pair of discs on the other shaft move further away from each-other, allowing the belt to ride on a smaller diameter, effectively changing the pitch diameter of each side and therefore changing the drive ratio. The belt tension remains almost constant with only slight variation during the shift cycle.

Originally, I've started this project in relation to a different one. my brother is a very skilled metal-smith and owns a metal shop for over 3 decades, (link to his web page) he is an amazing artist and his small factory is responsible for some incredible projects but usually he makes standard stuff on the routine basis. he wanted to build a Japanese style Black-Smith Power Hammer, and I love him so much I designed it for him. but we had an issue with controlling the speed and force of the blows… we saw all kinds of solutions that other people were using like belts on tires and friction clutches but nothing convinced us to be a solid long-term ,viable, do it yourself solution, so we didn't build the hammer, the CVT project was a theoretical solution for that problem… although I guess we could have modify and use a ready CVT out of an old scooter just the same.