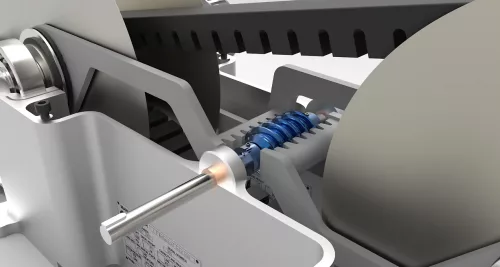

This simple and ingenious machine was designed and built by my company with a sole purpose in mind, to save human life at cement plants.

Polystyrene pump

תיאור

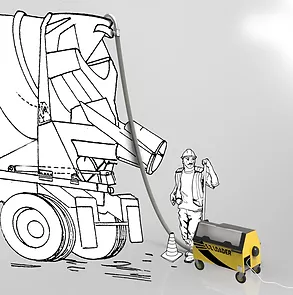

This simple and effective machine was invented with a very specific task in hand, to save construction workers from doing a very dangerous task…

its designed to inject EPS (Expanded Polystyrene) beads into a cement mixing truck. prior to the implementation of this device, 2 workers were needed for the task. one on the ground, passing the giant bean bags to the other worker which has dangerously climbed on an operating cement mixing truck, in order to empty the bags slowly into the rotating drum.

Usually EPS is added to the cement before other dry ingredients, meaning that this time consuming manual fill-up stage, had to interrupt the automatic handling of other materials added to the truck.

Developing this device becomes worthwhile from several main reasons:

A) simplicity of the design and build process of the device.

B) availability of ready shelf parts and technology.

C) a single client would normally buy several machines.

On the design aspect, the machine had to be protected from the harsh environment, mobile, compact and light, effective and easy to operate.

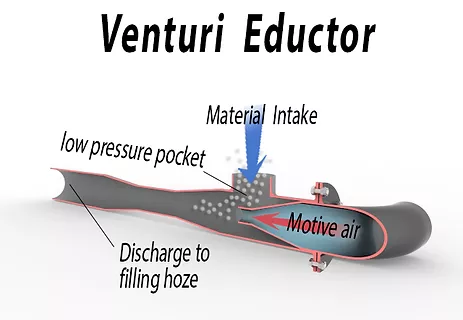

The main calculation needed to be made, were of the volumetric flow rate of the materials and air. it was taken under consideration that the volume of the EPS beads, and thus their shape, must not change in the process. Therefore the beads were not introduced into the blower's intake, where fan blades could damage their shape. Instead a "venturi effect" eduction method and an on-board hopper, were implemented. this was a fast and easy project, only 2 experiments were needed. The total time from realizing the problem in the work-site to finishing the proof of concept was less then 2 weeks.

by the nature of things,

cement needs to be dealt from localized plants. in these "small" branches which are pushed to maximize efficiency, time is a crucial resource. cutting the time needed for a production stage in the operation in half is a major deal.

Overall, this simple invention can save valuable production time and men power. it simplifies a complicated procedure, and can do the same job much better. in some countries the worker who climbed the mixer needs to be qualified for working in heights, and that means even more costs for his employer. the machine also saves waste and pollution in compare to the manual labor, as significantly less particles are suspected to be blown out of the mixer to the environment in the process.