Design from scratch and complete build of a unique, experimental casting machine, costume made for a world leading customer

RCM Rotational Casting Machine

תיאור

This was an extraordinary project! Working for this client was A great deal. Designing and building an incredible machine on a schedule that would have been considered tight for just brushing your teeth… My kind of challenge.

At the slideshow above, you can see some renderings of the design. Below there are pictures and clips of the final product and the build process.

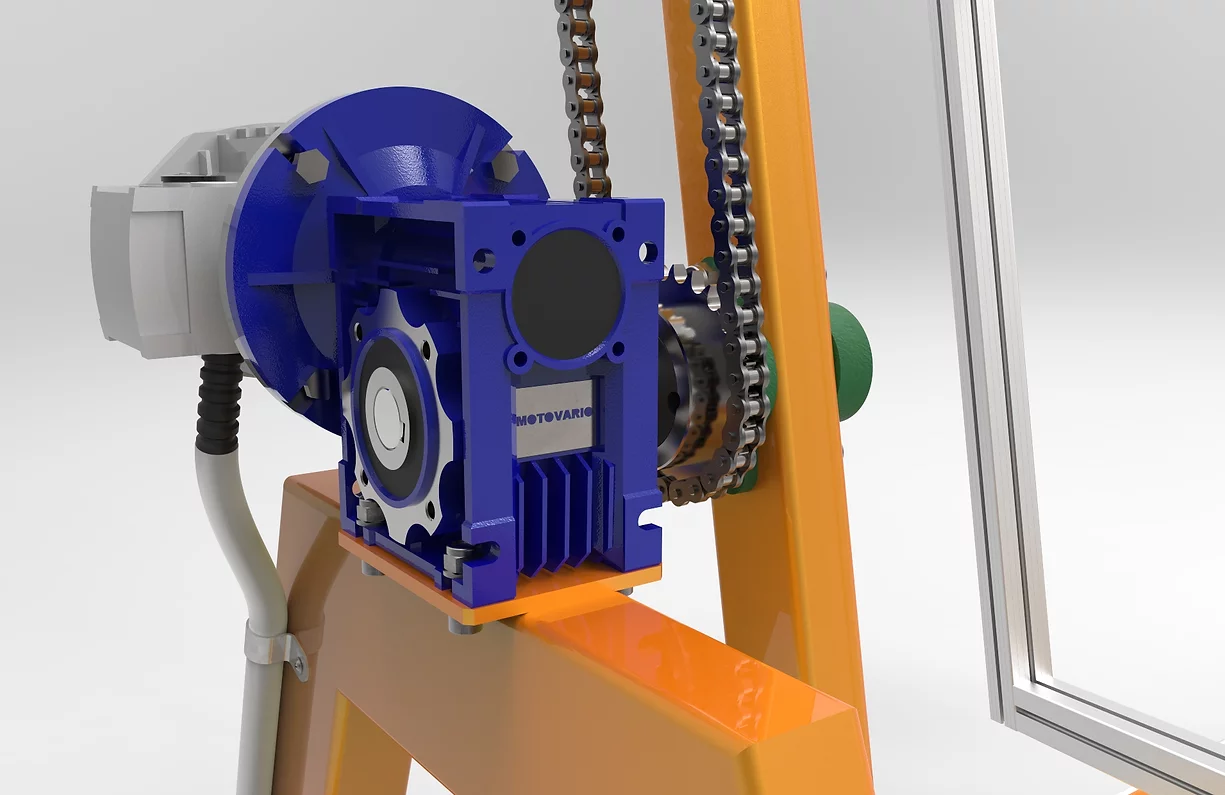

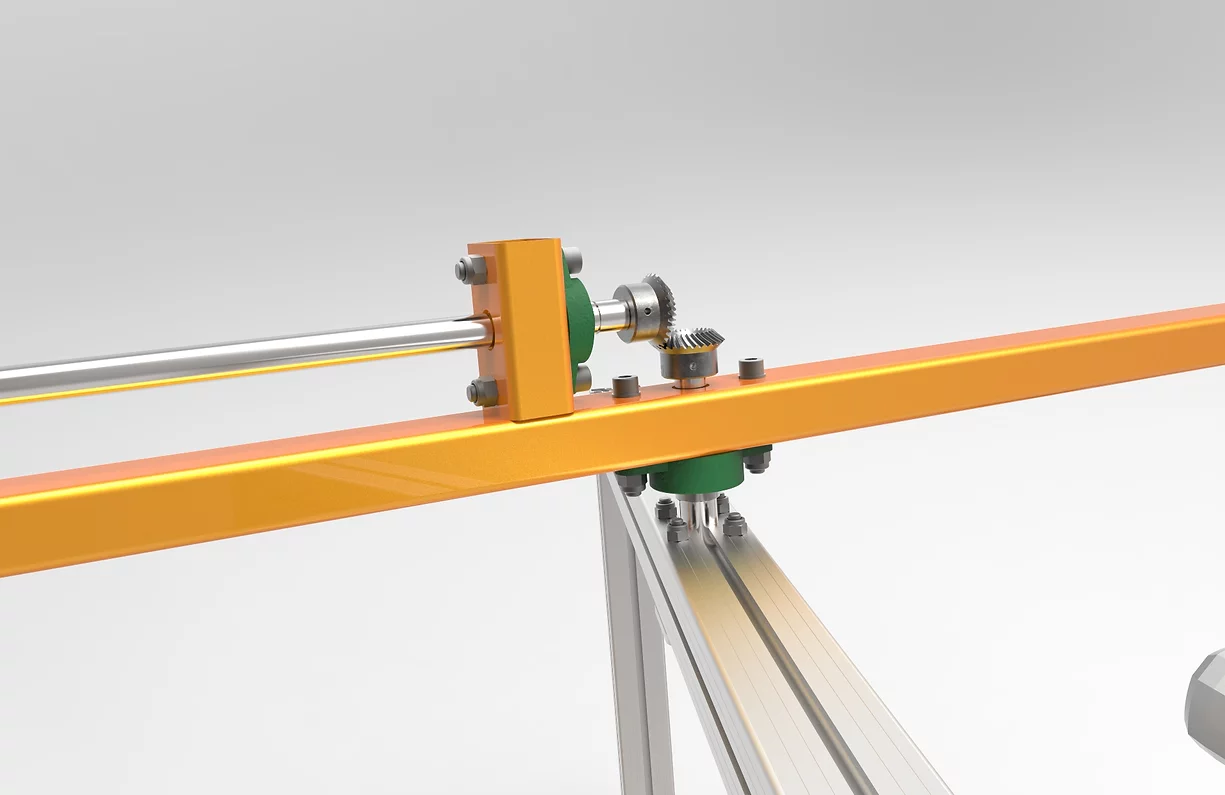

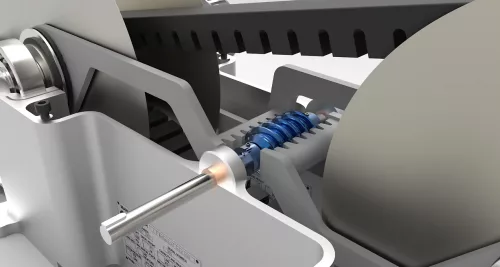

The machine, being an experimental device, had to be designed in accordance with future experiments procedures it needed to perform. Therefore it is different from the common "dual frames" rotational casting machines. The main difference is, it has 2 motors and drives, and therefore can independently control each frame's RPM. The system allows the user to program an Arduino Chip and create automatic, repeatable, operation sequences for results comparison.

The entire design and manufacture process took less than 2 months, from client demand lists to installation.

Some demands were very challenging, like operating with high torque at very low RPM, while the whole system must be single phase 220V. Or the intention to rotate heavy and uncentered molds at high RPM. A lot of calculations had to be made in a short time frame. Nevertheless, the design was super fun and the build was a dream! We built it all in house, from welding the frame and painting to calibrating and wiring the whole system. At last, we also guarantee the machine and provided our client with a full, custom made, technical owners manual, and we will service this machine for years to come.

The most amazing part is that in comparison to the import options available we provided the solution faster! cheaper! and with custom spec! along with overall better specifications. No wonder our client was amazed.

https://mtrl.net.technion.ac.il/2021/05/05/architectural-scale-rotational-casting-asrc/