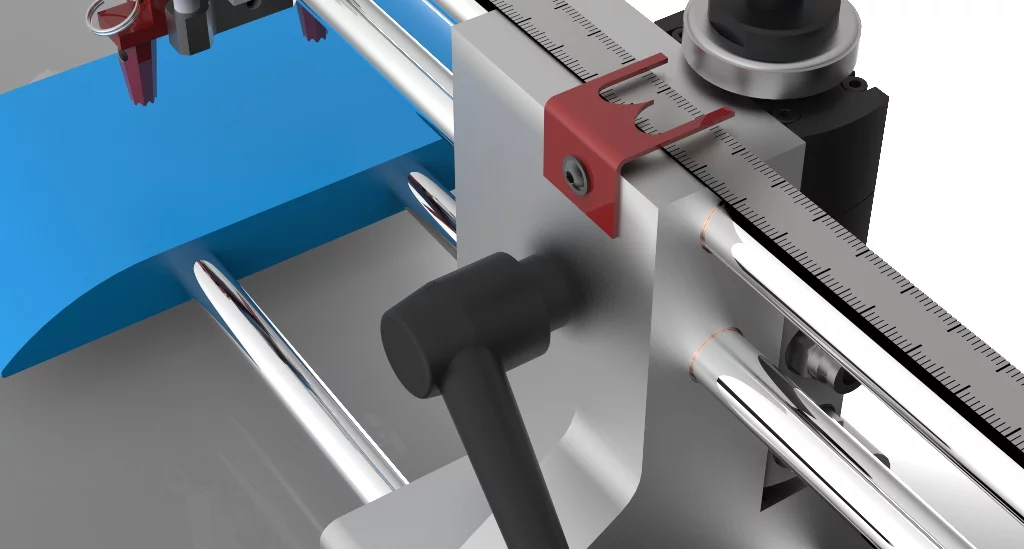

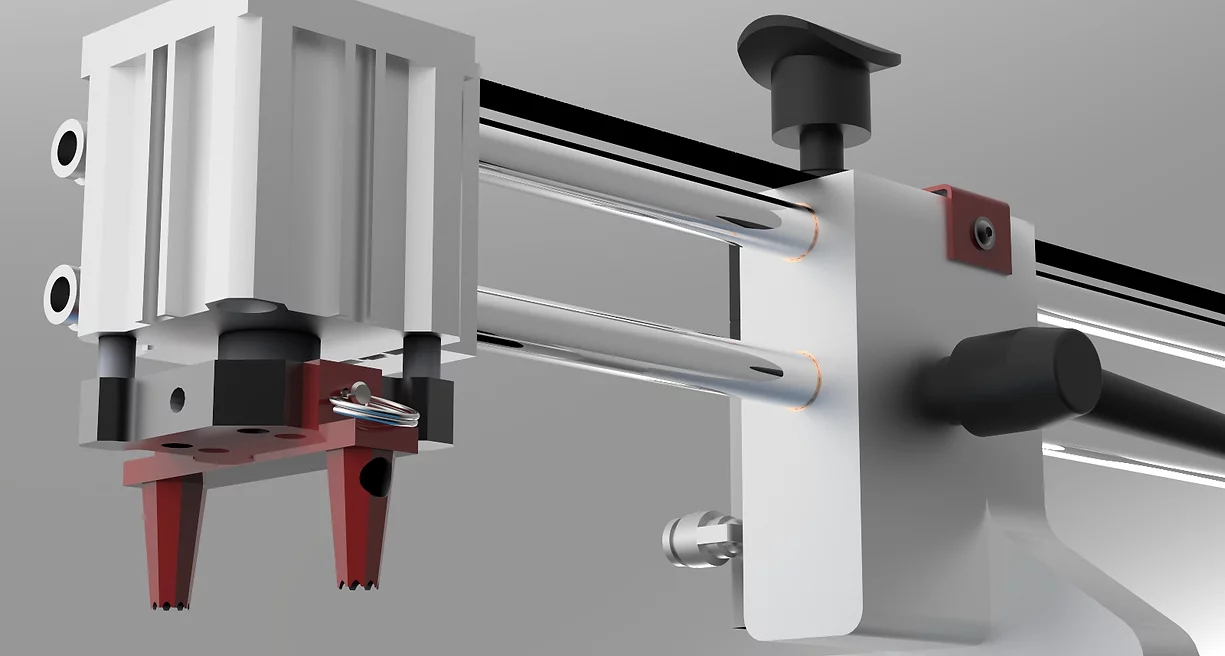

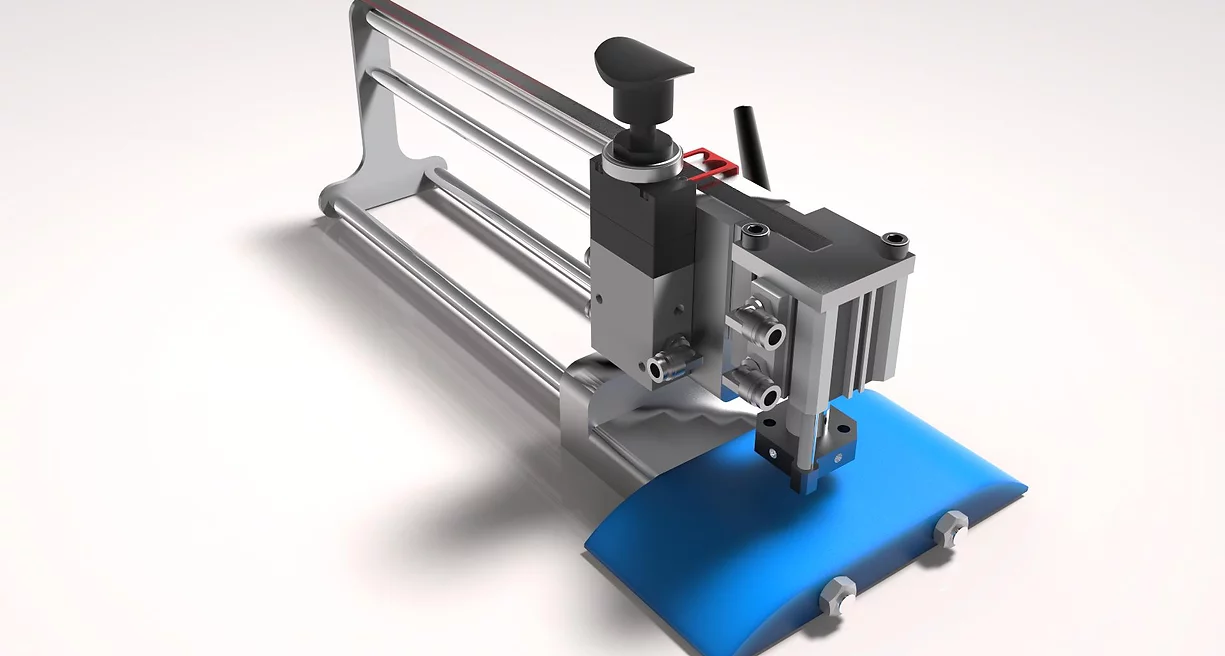

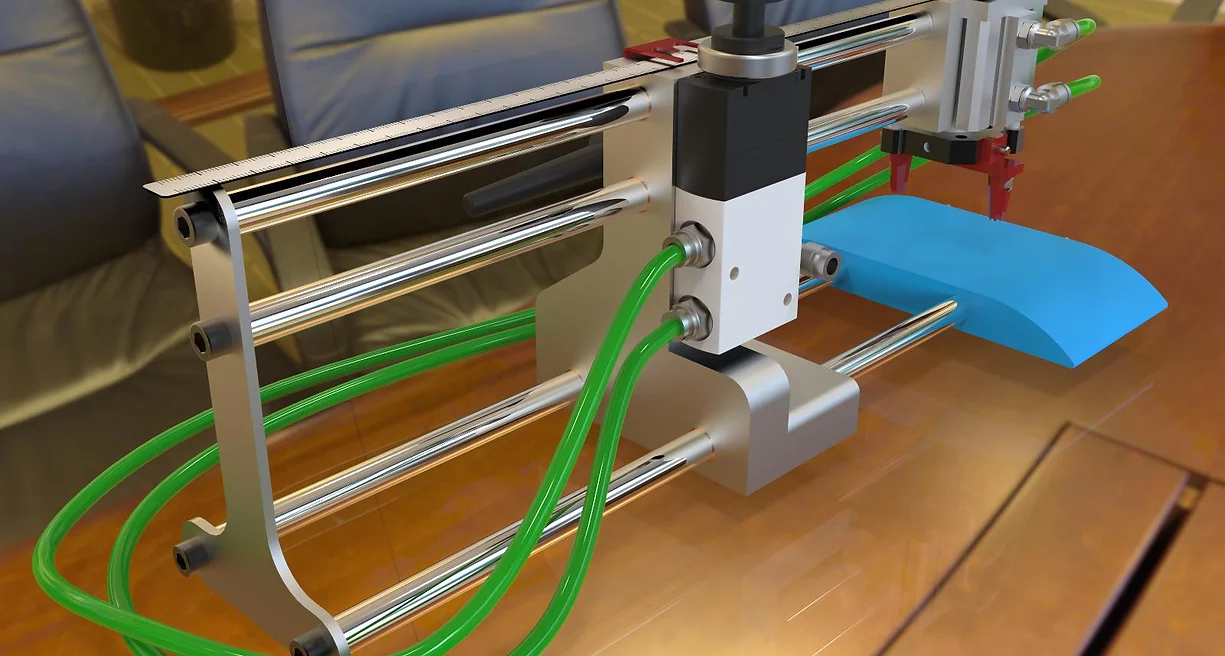

Custom made pneumatic perforation device for the trailer cover industry.

Pneumatic Perforating Device

Description

This was a custom order for a small shop who specialize in manufacturing and refurbishing trailer covers. The device wasn’t made to become a mass produced product and therefore was designed to be manufactured as a one-off piece. It’s a pneumatic replacement to the manual “hammer & hole-punch” work that had to be done rigorously. The goals were to ease the harsh task on the workers, to save time and reduce the processes cost by eliminating hand tools degradation. The design exceeded the expectations, and achieved all goals while retaining very low build costs, remarkable simplicity of handling and operation and a versatile ability to repeatedly make clean cut holes in a wide range of positions and diameters.

The Challange:

Replacing a hammer’s strike with a pneumatic actuator is not as straight-forward is one might think. and doing so to perforate 2 layers of thick cargo straps and PVC sheets, is that much harder. I met allot of skeptic opinions along this road. a hammer strike concentrates allot of kinetic energy on a very small surface to create incredible amount of pressure at the shearing edge. but the difficult thing to imitate was the speed in which it all happens. Theoretically you could create any pressure you want with the corresponding piston and air pressure. but pneumatic actuators (even the fastest ones) tends to build-up the pressure rather than giving it all up instantaneously. That tiny interval of time allowed the flexible materials to bend and energy was wasted on forming elastic deformations. The first test involved 410 Kg of force (using an 80 mm piston with 8 Bar)

and it was not nearly enough to make the double 6 mm holes job. designing or buying an expansive “Impact system” to better mimic the hammer’s work was way to costly, I’ve solved it with creative thinking instead.

A design of another manual and less versatile perforator, that I made for the same client

The Design:

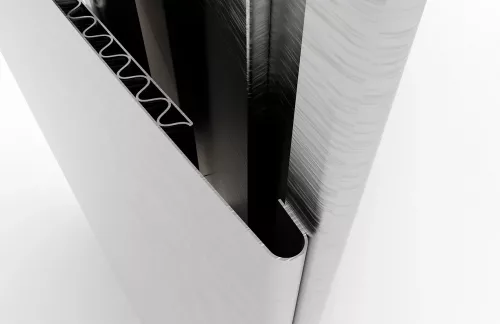

To overcome this problem, I took 2 different approaches. the first was to replace the sharp hole-punch with a custom made shearing Die. It was a bit costly and hard to source as it had to be custom made and we were talking about a one-off model. but eventually this was the most intuitive and simple solution. to prove its suitability we made a sample die in our CNC machine and repeated the first test with a sharper hole- punch and the die beneath it, it cut brilliantly. we concluded that a professionally made die should preform even better and last long enough to be feasible.

the second approach was considered due to the die’s price.

I realized that the tough Kevlar Cargo Straps were of polymeric nature and therefore relatively heat sensitive. heating the cutting edge to about 140 C seemed to be a very practical solution. and when a die will eventually wear, this was much more promising. But it had 2 down sides to it: first, we now also need a 12V supply to the system. and secondly, we have to deal with a worm hole punch that is accumulating the cut pieces and continually heating them up until the discharge… I could have addressed these issues easily, but the “”semi-professional”” die was eventually used.